18.10.19

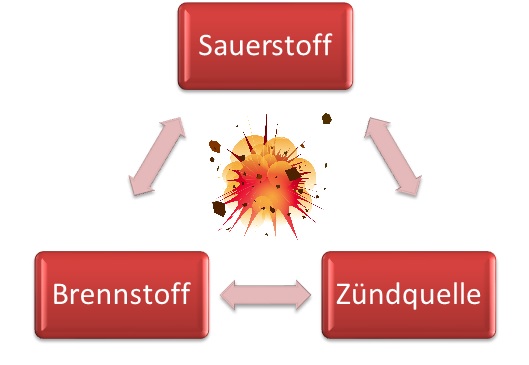

Explosion protection is one of the most safety relevant tasks in a company. In extreme cases, the life and health of employees can be massively at risk due to large thermal and pressure effects. For this reason, it is imperative to take measures to prevent such accidents.

The European Directive 1999/92/EC provides minimum requirements for improving the health and safety of workers potentially at risk from explosive atmospheres.

Each employer is responsible for the workers in his area and coordinates the implementation of all measures relating to the safety and health of the workers.

The requirements for the preparation of an explosion protection document are specified by national employer regulations, such as the German Industrial Safety Regulation (Bl. I S. 49) or the Austrian Explosive Atmospheres Regulation (VEXAT) - StF: BGBl. II Nr. 309/2004. The naming of explosion risks and the taking of appropriate measures must be part of an explosion protection document.

If the safety concept is not well thought out with regard to explosion protection, it may be that, despite appropriate technical precautions, a large amount of additional organisational measures must be taken in order to achieve an adequate level of protection against the explosion risks. This means that in addition to the use of CE-compliant equipment and protective systems, attention must also be paid to testing activities, personnel qualification and relevant training and instruction.

So when is an explosion protection document required?

-

Releases during internal transport, conveyance or storage

-

Processing steps (mixing/grinding/grinding, material application/coating processes, etc.)

-

Concentration and deposition of flammable substances, for example in conveyor, separator/filter systems

-

Evaporation of flammable substances, e.g. during drying processes

-

Chemical and thermal processes/reactions (such as incomplete combustions, fermentation processes, charging processes of batteries/energy stores, evaporation, etc.)

-

Leaks and releases of substances when handling media (dilution, blending / mixing, spraying, swirling)

-

Supply of oxidising substances/oxygen or elimination of inert substances

The explosion protection document must be drawn up before commissioning a plant or before commencing work.

Existing risk assessments, documents or equivalent reports can be integrated into the explosion protection document.

Further information on "What does my explosion protection document have to contain and what are the reasons for updating this document" can be found in the next part of our explosion protection series.