- Identification of the necessary safety functions

- Determination of the necessary safety integrity level (SIL)

- Support in creating a shutdown matrix / control concept

- Creation of the Safety Requirements Specification (SRS)

- Support in selecting/testing components

- Calculation (verification) of the safety functions

- Performing software validation (B&R; Siemens)

- Performing hardware validation

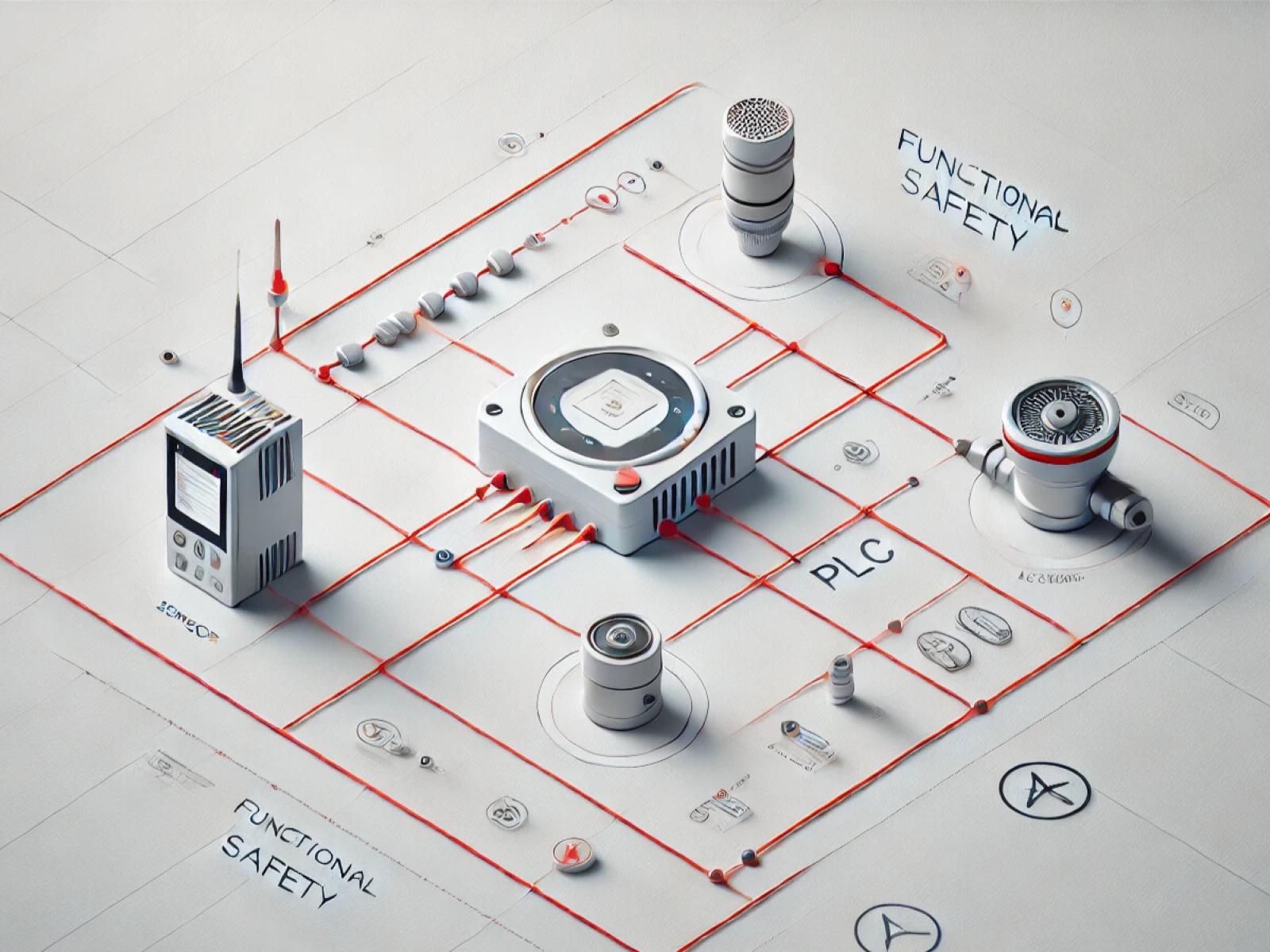

Functional safety according to EN 61508 and EN 61511 is crucial for safe operation in the process industry. These standards cover the entire safety life cycle and ensure that safety-critical systems operate reliably. A safety function always consists of three main components: sensor(s) (e.g. temperature sensor(s)), a logic unit (controller) and actuator(s) (e.g. valve(s)), which work together to ensure the safe state of the process.

A hazard and operability study (HAZOP) is conducted to identify potential hazards that could affect operation. Based on this analysis, the necessary safety functions are defined. This is also where the required safety integrity level (SIL) is determined, which defines how reliably the safety functions must work to minimize the risks.

After the creation of the Safety Requirements Specification (SRS), which captures all the requirements for the safety functions, the safety-related components are selected and verified. This specification is crucial to ensure that all the requirements for the components and the function itself are precisely defined.

This is followed by the verification (=calculation) of the safety functions. This ensures that the safety-relevant parts and the architecture of the functions are able to achieve the defined safety objectives with regard to random and systematic failures and to provide the required risk reduction.

The software validation is then carried out. This checks whether the safety-critical software meets all safety-related requirements and has been properly implemented.

This is followed by the hardware validation, which checks whether the intended safety-related functions meet the requirements of the SRS. Checks include whether components have been correctly installed and whether the function itself and the necessary diagnostics are working properly to ensure their proper operation. In addition, it is verified whether all formal criteria, such as the availability of all relevant documents, have been met.

Rely on safe and reliable processes – contact us for a comprehensive implementation of compliant safety features.