- List of necessary documents

- Conducting/moderating the HAZOP study in accordance with EN 61882

- List of standard-compliant countermeasures using LOPA or risk assessment in accordance with EN 61511-3

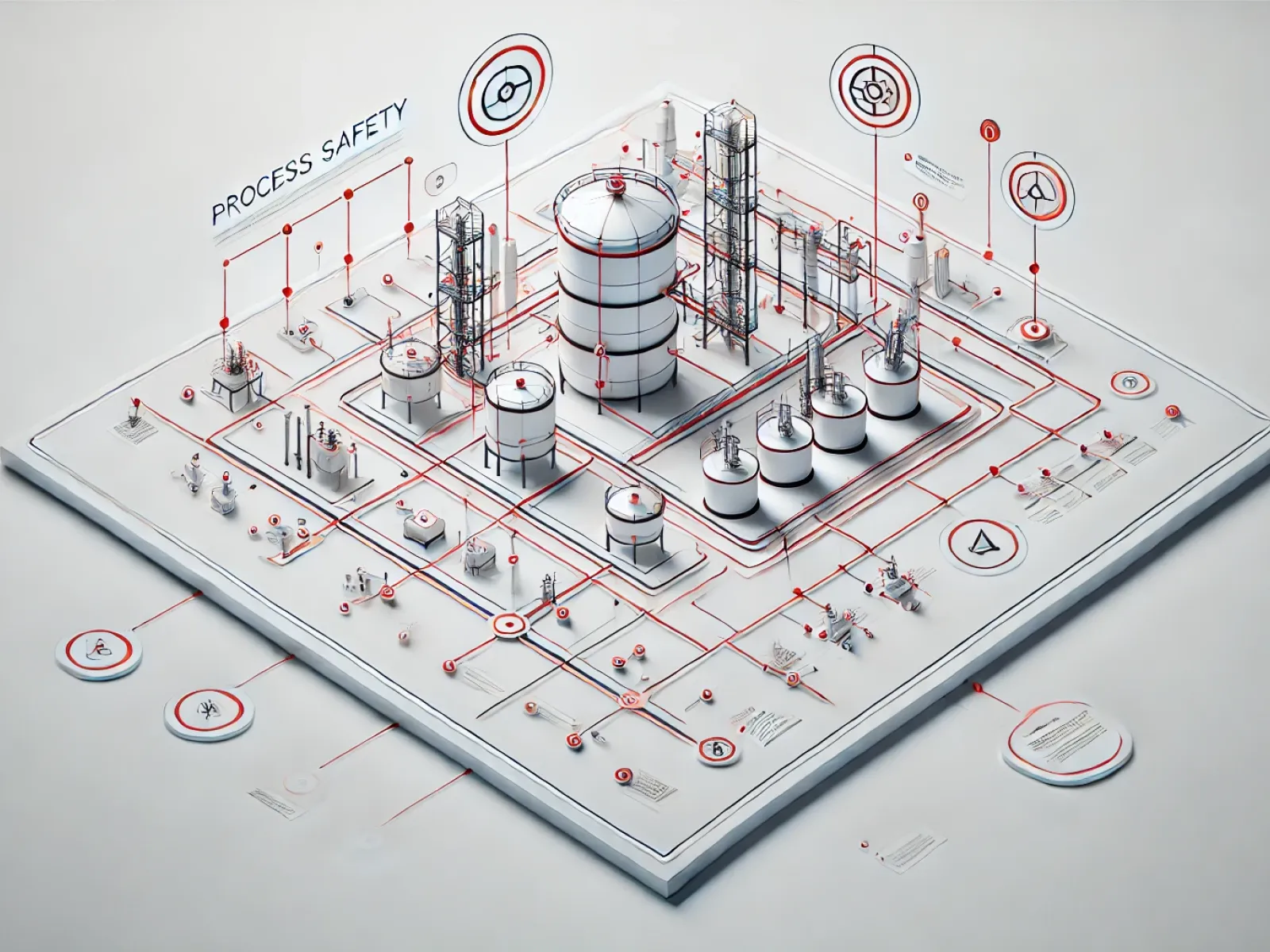

The HAZOP procedure according to EN 61882 is a systematic tool for analyzing plants and processes, particularly in industries such as the chemical, petrochemical and pharmaceutical industries. The aim is to identify and evaluate potential sources of risks and operational disruptions in order to increase safety and efficiency.

The process begins with the preparation of the HAZOP study. This involves collecting the relevant documents, such as technical drawings, process flows and operating instructions. This targeted preparation facilitates a precise and practical evaluation during the HAZOP analysis.

The execution of the HAZOP study is carried out by the HAZOP team, which includes a range of different experts. In moderated sessions, the existing processes are analyzed to identify possible sources of risks and deviations from standard conditions. Each potential hazard identified is then examined and classified in detail.

For the risk evaluation either the LOPA (Layer of Protection Analysis) method or one of the risk graphs according to EN 61511-3 is used, depending on the requirements and complexity of the system. These methodologies help to assess the impact of safety gaps and to determine the need for additional protective measures. LOPA can be used to precisely analyze the various levels of protection in a system, while EN 61511-3 offers different risk graphs for evaluating and quantifying risks.

Listing suitable countermeasures also plays a central role, and these are formulated at the end of the study. These countermeasures, which include both technical and organizational recommendations, ensure that all identified risks are sufficiently minimized and that the plant meets the applicable safety requirements.

The combination of thorough documentation, standards-compliant analysis and precise risk assessment using proven methodologies not only ensures compliance with legal requirements, but also guarantees safe and efficient operations in the long term.

Together, we can make your processes safe. Contact us for customized solutions for your safety requirements.