- Creation of explosion protection concepts for project submission, including preliminary zone classification (prior to implementation)

- Creation of explosion protection documents for existing (operating) systems or projects that have already been implemented, including zone classification and standard-compliant countermeasures

- Creation of a zone plan

- Creation of a list of work equipment as a basis for initial and recurring tests

- Assessment of an intrinsically safe system acc. EN IEC 60079-25

- Implementation of (recurring) instruction

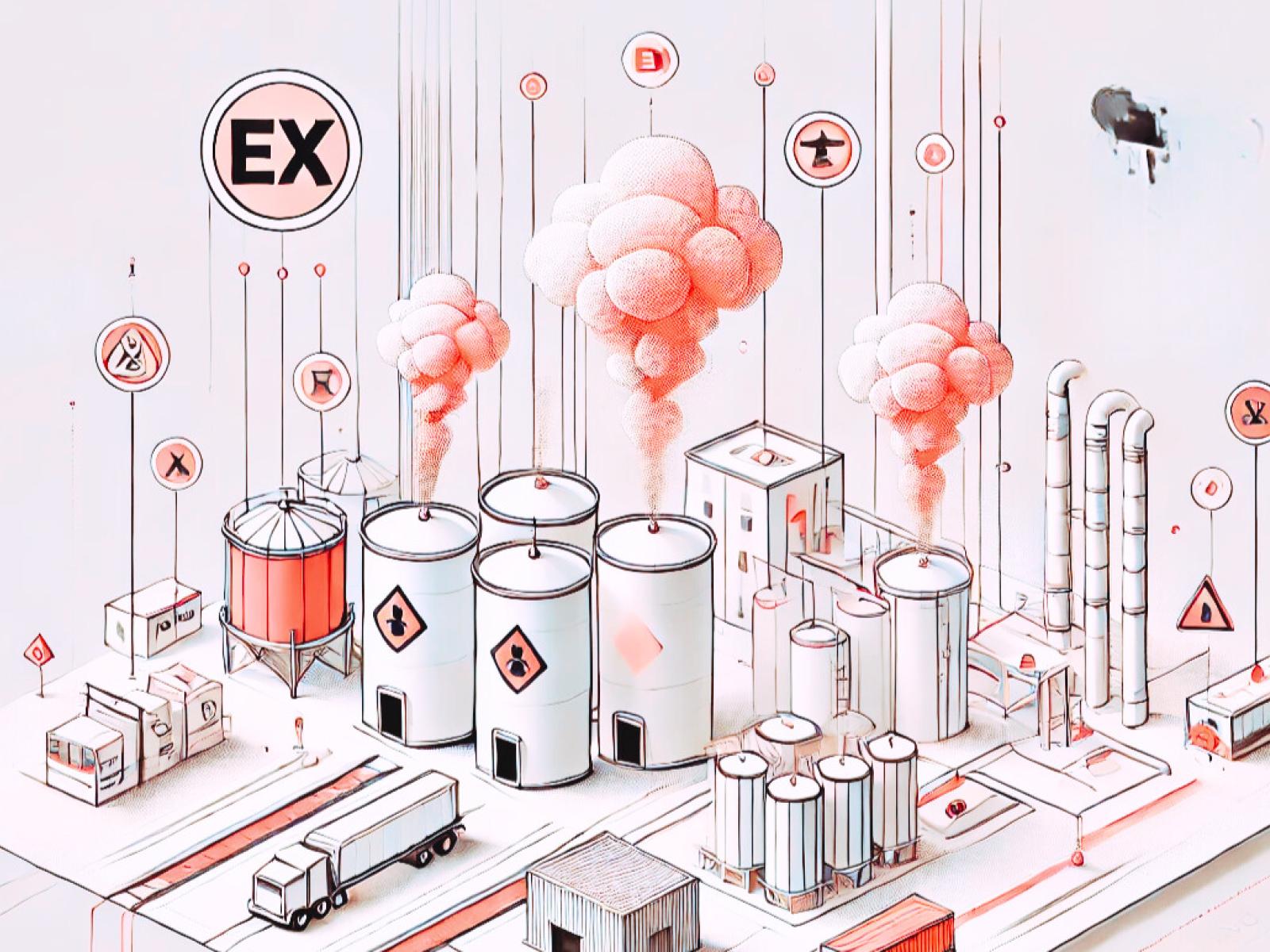

Explosion protection at the workplace ensures that potential explosion hazards in work areas are detected and controlled at an early stage. When using combustible substances, it is an important aspect to be considered when identifying and assessing hazards. In the EU, Directive 1999/92/EC regulates explosion protection for employees. For operators of plants with potentially explosive atmospheres, extensive protective measures are required to minimize the risk of accidents and ensure safety.

Explosion protection concept vs. explosion protection document:

When planning and submitting a project, it is necessary to create an explosion protection concept that defines all measures to be taken during implementation. Before the plant is put into operation, an explosion protection document is created that describes how the plant is operated safely and which measures are implemented to minimize risk.

Primary, secondary, constructive and organizational measures are the cornerstones of a functioning explosion protection. These measures include both technical precautions to prevent explosive atmospheres and to avoid ignition sources and minimize the effects of a possible explosion.

Zone classification and labeling:

Another central element in explosion protection is the zone classification. Potentially explosive atmospheres must be clearly defined and marked as zones to ensure that only suitable equipment is used in the respective areas. The correct labeling of potentially explosive atmospheres and the selection of suitable explosion-proof equipment, tools and personal protective equipment are crucial to avoiding ignition sources and reliably preventing the occurrence of an explosion.

Instructional training plays a crucial role in explosion protection. Employees must be informed regularly about possible hazards and the safety measures taken. These training sessions are not only a legal requirement, but also contribute significantly to the prevention of accidents. Documented verification of the training is of great importance in order to be able to prove compliance with the regulations to the authorities.

Regular inspections:

In addition to regular cleaning and maintenance work, organizational measures also include periodic inspections of work equipment, such as ventilation systems or other technical facilities that ensure the avoidance of potentially explosive atmospheres – i.e. zones – or are used within them. These inspections ensure that all technical systems are functioning properly and meet the applicable safety standards.

Protect your employees and facilities with comprehensive explosion protection – from zone classification to regular instruction. Contact us for customized solutions in explosion protection.