Are you responsible for the layout of safety-related steering groups? How are the requirements concerning the reliability/ probability of failure of the steering group? Which calculations, documents and evidence are necessary for the whole safety-related control system and how should they be written? Do you want a cheap solution with mostly existing components instead of expensive new components?

With us you are on the safe side!

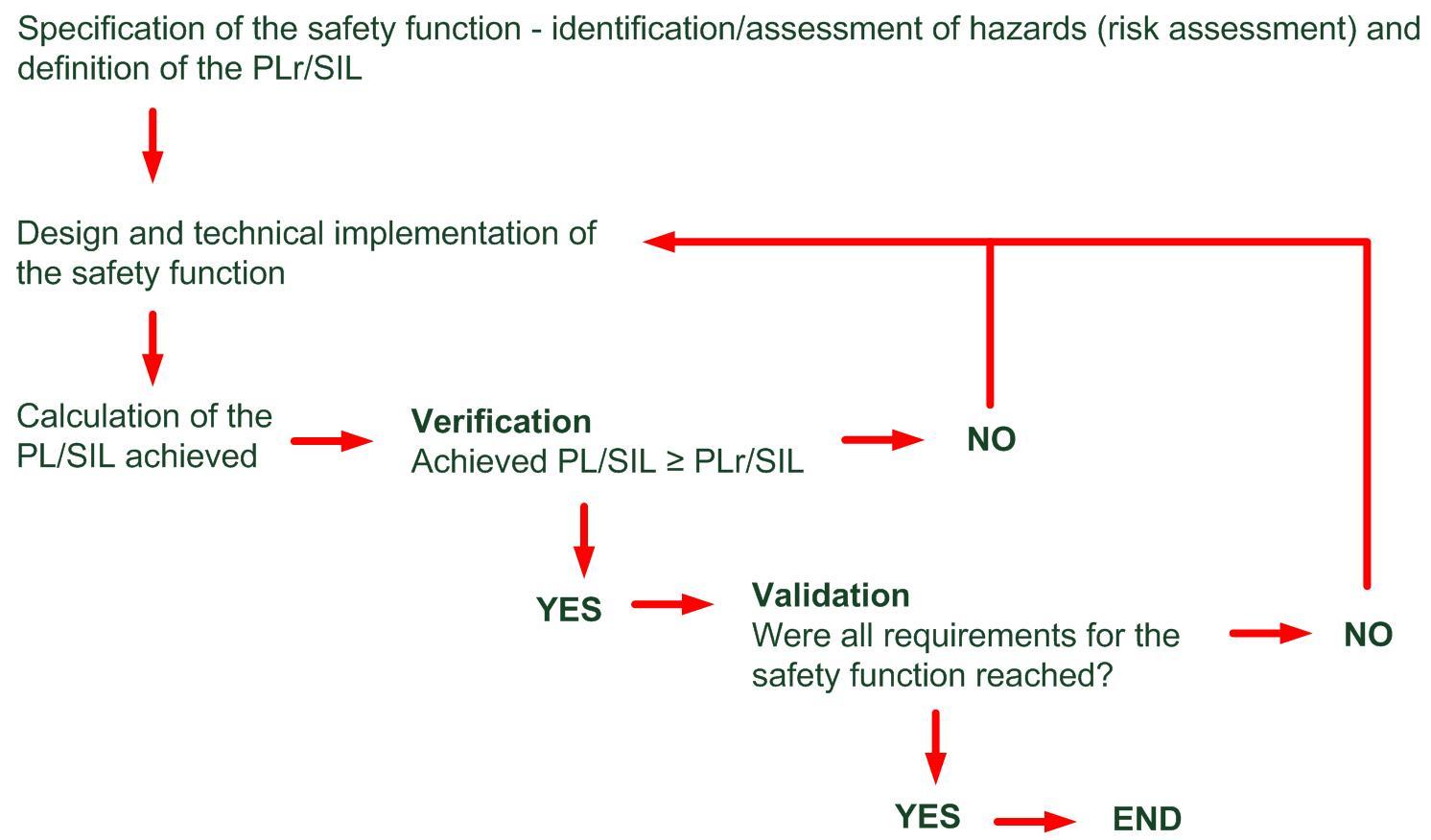

The development process of safety circuits for machines, processes and plants is always linked with the proof of the ability to effect the function under predictable conditions. The producer/developer of the safety-related control system is liable to perform the verification and validation for each safety function pursuant the standard which should be used. According to the adaptation the proof of the fulfillment of all requirements on the PL (Performance Level), SIL (Safety Integrity Level) or ASIL (Automotive Safety Integrity Level) has to be brought and standardized documented.

Verification (PL/SIL/ASIL-calculation) and validation (among others the functional test):

-

of machines based on EN ISO 13849-1/2 and EN 62061

-

in the process industry based on EN 61511-series of standards

-

in the automobile industry after ASIL EN 26262- series of standards

-

Implementation of a FME(D)/(C)A//FTA (Failure Mode and Effects and Diagnostic/Criticality Analysis//Fault Tree Analysis)

-

Support with the fundamental development of safety-related steering groups

-

using tools such as SISTEMA and SOFTEMA, as well as manufacturer tools

Practical example

A renovation respectively a new built of the inching mode (safe, reduced speed/ crawling speed) of an old machine shall take place pursuant the current technical regulations.

Renovations on an existing machine issue a special challenge to the constructor of the safety-related steering group. The PLr/SIL will be preset on the basis of the risk assessment. In many cases for the sake of convenience old components are just exchanged for new components, which reach the claimed PL/SIL. These solutions are often combined with high costs. Through an intelligent hardware architecture, which uses existing components, it’s also possible to reach the necessary PL/SIL but with a significant cost saving.

Reach your goals together

Do you need support and consulting for questions concerning functional safety ("fusa")? Then utilize our yearlong experience. We are the right person of contact and help you to realize budget-friendly solutions.