Are flammable substances and media used in your company or do they arise in the course of processing operations and processes? Are you a manufacturer of a piece of equipment, a machine or a plant equipped with electrical equipment or mechanical components which are operated in an explosive atmosphere? Do you want to start with the prevention or reduction of an EX-zone by suitable "dense" designs and need support?

We are your partner when it gets explosive!

We offer you answers and solutions regarding the necessity of additional protective devices, "safety-oriented" design of protective systems, possible prevention of an ignition source in the presence of an explosive atmosphere, suitability of equipment, design of constructive explosion protection devices (pressure relief devices, explosion suppression systems etc.) and much more.

We can offer you as a manufacturer or operator our support in various areas:

-

ATEX Product Directive 2014/34/EU

-

ATEX Operator Directive 1999/92/EC

-

Definition and limitation of operating conditions

-

Definition of EX protection requirements (such as selection of explosion protection group, category, temperature class etc.)

-

Assessment of all potential ignition sources and newly purchased parts for their suitability

-

Preparation and testing of technical documentation and user information according to ATEX Directive 2014/34/EU and ATEX Operator Directive 1999/92/EC, as well as their national implementation (e.g. VEXAT)

-

Preparation of a zone plan or explosion protection document

Praxisbeispiel

The agitator I put on the market is intended for mixing solvent-based paints. There is an EX-zone 0 in the container. Which requirements or restrictions apply to my product? Can I use unlimited "insulating" plastic parts?

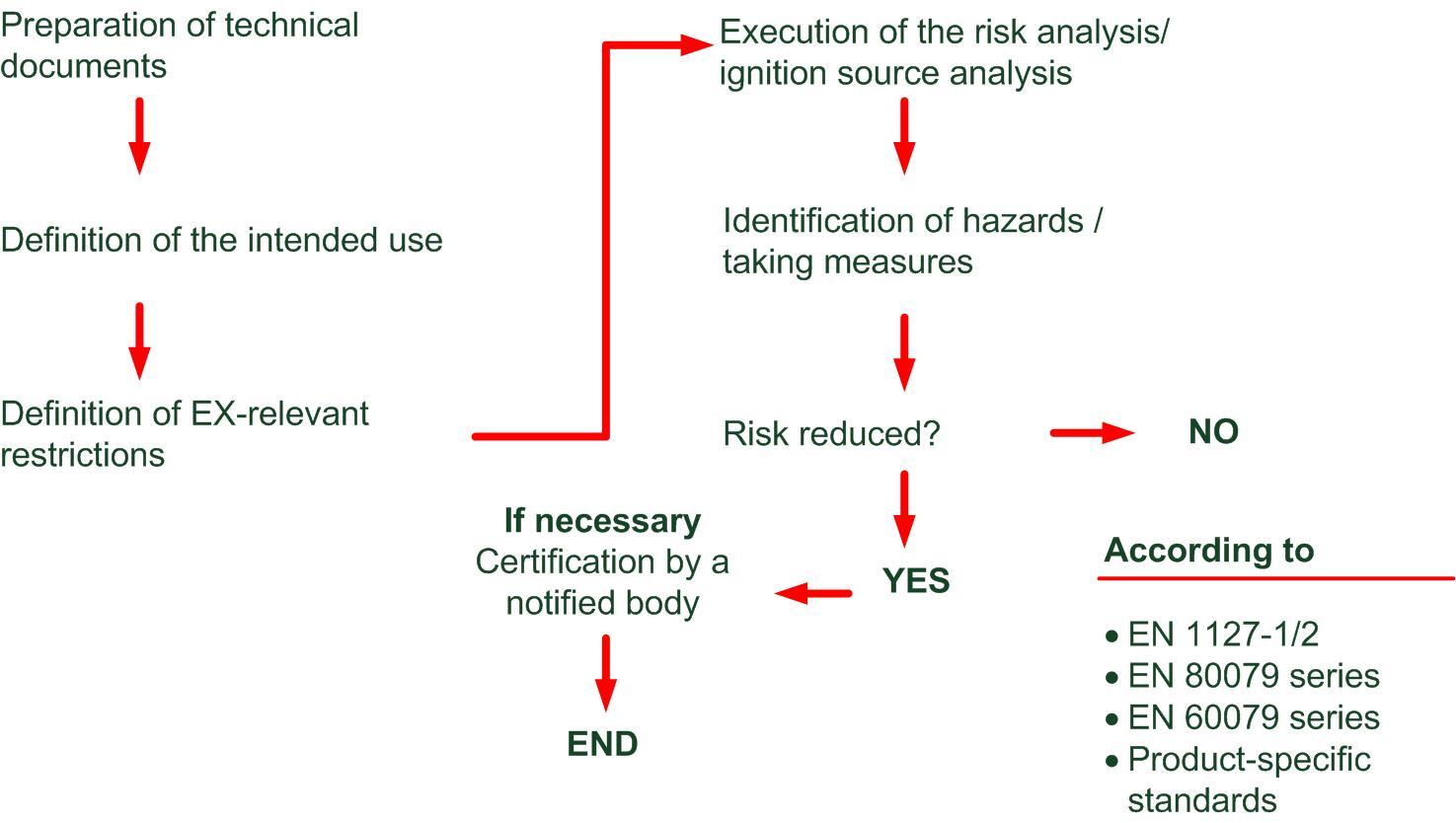

A CE conformity assessment procedure must be carried out for an agitator, including ATEX Directive 2014/34/EU. The requirements, such as EX-category, ignition temperature, etc. are defined, all potential ignition sources are assessed (ignition source analysis) and finally suitable measures are taken. The same applies to electrical equipment such as wiring. Before issuing a declaration of conformity and affixing the ATEX marking, an operating manual must be prepared and the agitator must be approved by a notified testing laboratory due to the operating conditions in EX-zone 0.

Reach your goals together

You know about the dangers of an explosive atmosphere but have neither the time nor the possibility to deal with it intensively? Do you need an explosion protection document or help with the CE conformity assessment procedure? Then take the opportunity to get advice and support from us.