17.06.21

The European Pressure Equipment Directive 2014/68/EU (PED for short) came into force on 19 July 2016. It applies to pressure equipment and assemblies with a maximum allowable pressure (PS) of more than 0.5 bar. This article is intended to provide an understanding of how to deal with the PED with regard to the correct classification of vessels or boilers with two or more chambers.

For classification according to the PED, the maximum permissible pressure (PS), the maximum permissible temperature (TS), the volume (V) and the fluid used are required right from the start.

Fluids are divided into 2 groups according to the PED:

- Group 1 fluids - dangerous

and - Fluids of group 2 - non-hazardous

Vessels or boilers with several chambers, fluids, temperatures and pressures are considered as one pressure equipment according to the PED. Each chamber is to be classified individually and the chamber with the highest classification then determines the final category of the entire pressure vessel.

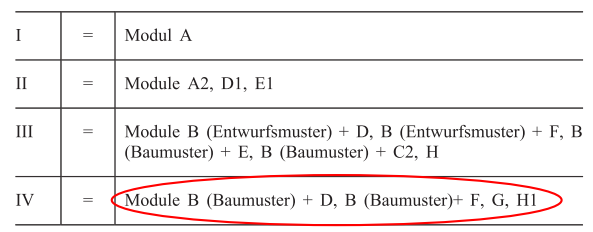

The category is then used to determine the options of the modules for conformity assessment. (See Guideline B-19 - PED 2014/68/EU).

This means that chambers which are normally to be manufactured according to "good engineering practice" (Article 4, paragraph 3 of the PED), as described above, fall into the conformity assessment procedure of the highest category.

Note for volume determination:

- Fixed, internal equipment, e.g. agitators, lances, etc. are volumetrically recorded and deducted from the total volume of the container before classification. The volume of connecting pieces is added up to the first connection and can account for a considerable proportion.

If all fluids and all data relevant for classification are known for each chamber, the correct diagram is selected according to PED Article 4(1). The diagrams can be found in Annex II of the PED.

Concrete example using a plate heat exchanger with 2 chambers of 600 litres each (see illustration above right):

Illustration: Example plate heat exchanger as defined by the PED to be seen as a container with 2 chambers.

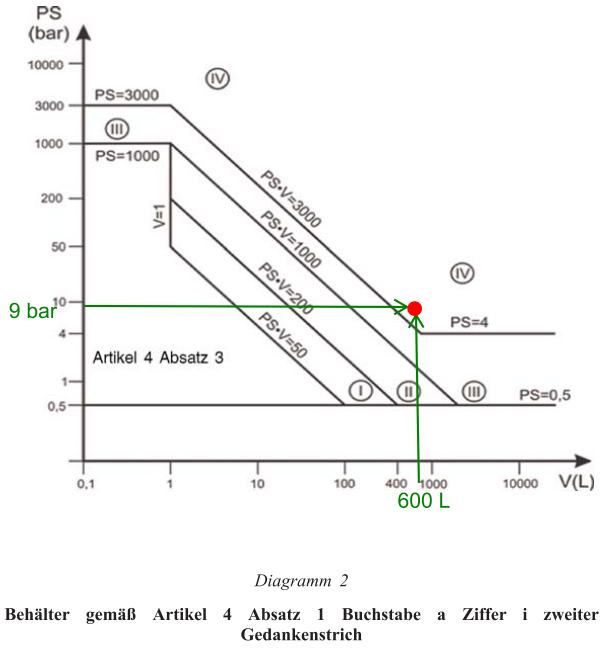

Chamber "ORANGE": PS = 9 bar, TS = 300 °C, V = 600 L, Fluid: Group 2, Gas à Diagram 2

PS ∙ V = 5400 bar∙L >3000 bar∙L

- Category IV pressure equipment

Extract from PED 2014/68/EU, Annex II Diagram 2

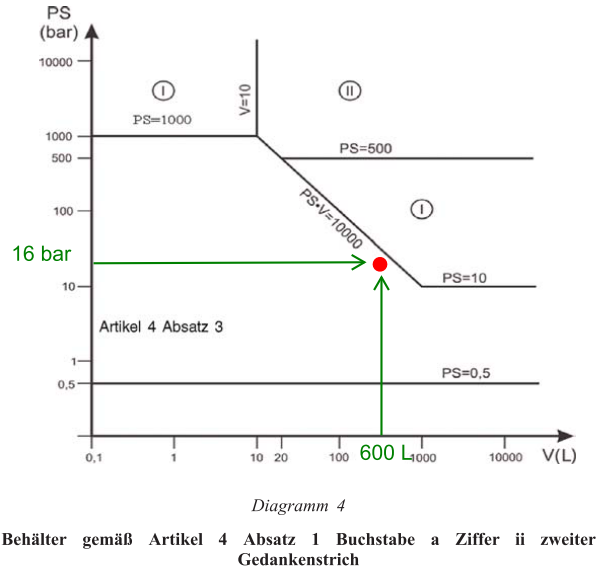

Chamber "BLUE": PS = 16 bar, TS = 170 °C, V = 600 L , Fluid: Group 2, liquid à Diagram 4

PS ∙ V = 9600 bar∙L <10000 bar∙L

- chamber would normally be manufactured according to Article 4(3), according to "good engineering practice".

- Because it is part of the whole heat exchanger, it is therefore also subject to the higher category, here category IV.

- the whole conformity procedure is according to modules B (type) + D, B (type) + F, G, H1.

Extract from PED 2014/68/EU, Annex II Diagram 4

This procedure generally applies to tanks, heat exchangers, coolers with several chambers, even if the heat exchange takes place via tubes, a jacket, plates, etc.

We will be happy to provide you with further advice on the Pressure Equipment Directive 2014/68/EU.