26.03.20

Standards news: EN 1127-1:2019 Explosive atmospheres - Explosion prevention and protection - Part 1: Basic concepts and methodology

In August 2019 the new edition of the standard EN 1127-1:2019 Explosive atmospheres - Explosion prevention and protection - Part 1: Basic concepts and methodology was published by the European Standardisation Institute (CEN).

This set of rules is important for both MANUFACTURERS and OPERATORS of machines, devices, plants and systems in the field of explosion protection.

As soon as materials, substances and conditions can create an explosive atmosphere, the methodology of

- risk assessment and

- risk reduction

have to be used.

This includes the consideration of incidents.

The method of risk reduction (risk prevention)

- starts with the planning and design of systems (restriction of substance release sources and ignition hazards),

- evaluates technical protection measures,

- includes the determination of (recurring) maintenance/repair and testing costs, their scope and the requirements on personnel,

- considers possible monitoring and emergency measures

- and ends with the correct behaviour of people.

The principles of EN 1127-1 should be applied when creating conditions that ultimately allow an employer to prevent explosions. Part 2 of the EN 1127 completes the principles and methodology of explosion protection in mines.

The new edition of EN 1127-1:2019 contains among others the following MAIN CHANGES compared to the previous version EN 1127-1 with issue date 2011

-

Here we would like to emphasize the topic of "tightness" of systems and devices.

- The execution and use of the correct terms is of great importance at the latest when defining EX-zones or when aiming for the exclusion of an EX-zone and the corresponding selection and/or necessity of ATEX-certified equipment.

- In the old EN 1127-1:2011 the assessment of "tightness" was defined by the terms "permanently technically tight" and "technically tight".

- In the 2019 edition, the assessment of "tightness" was determined by the new terms "normal tightness" and "enhanced tightness".

- The statement about a tightness and whether accordingly a release/leakage of a flammable/flammable substance is to be expected is determined/certified by the manufacturer of a system.

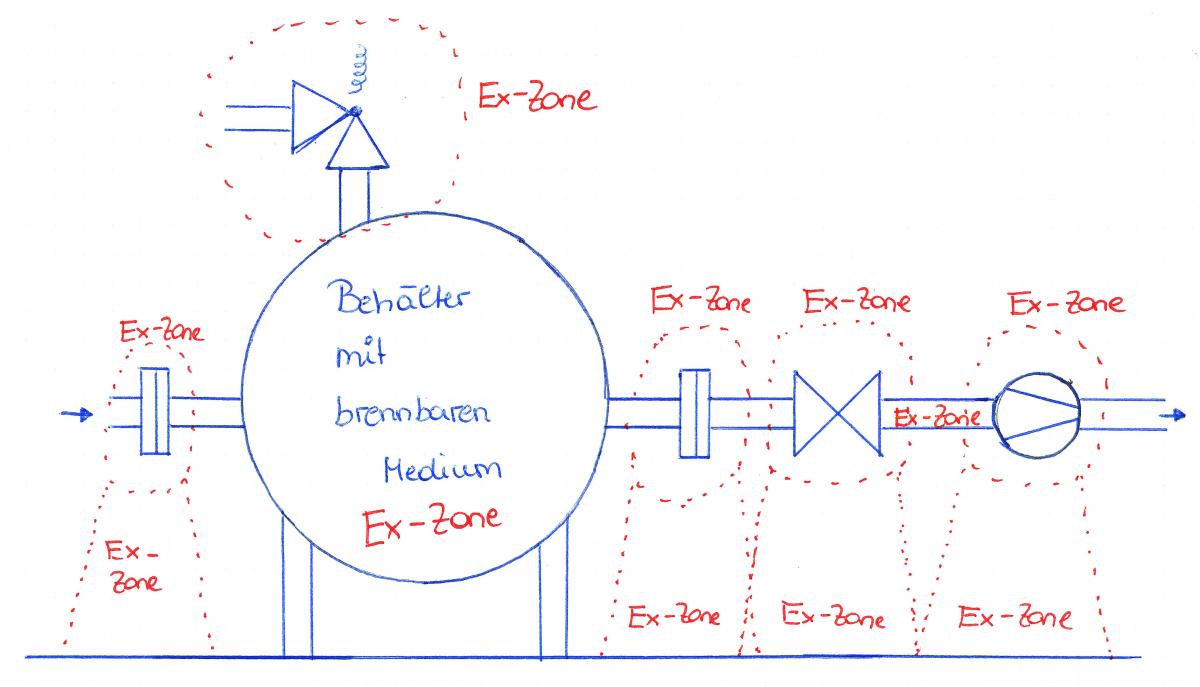

For example: EX zone with "normal tightness"

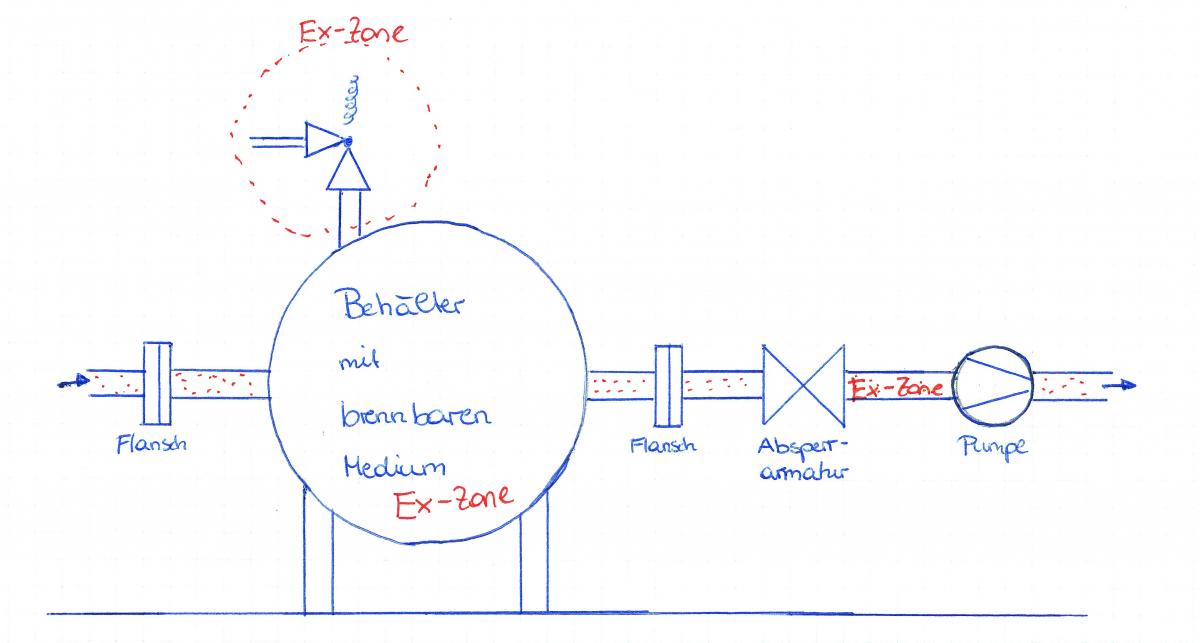

For example: EX zone plan for use with "extended technically tight" devices

Further changes in the revision of EN 1127-1:2019 are

- Specification of the explosiveness of hybrid mixtures, aerosols, mists and suspended particles with particle sizes larger than 0.5 [mm].

- Additions of explosion protection relevant material parameters and ignition properties.

- Addition of possible situations and parameters that determine the effects of a possible explosion.

- Concretisation of ignition hazards and their evaluation criteria, including "static electricity", "cathodic corrosion protection/electrical equalising currents", ignition hazards due to various radiation sources, ultrasound, etc.

- Additional/modified cross-references to current technical standards; use of current terms and definitions.

If you are unsure whether these changes affect you as operator or manufacturer of a machine/system, we will be happy to help you and examine your case individually.

Please contact us!

Please contact us!